How Dirty Anilox Rolls Impact Color in Flexographic Printing

In the world of flexographic printing, color consistency is everything. Printers depend on precise, repeatable results to meet customer expectations, reduce waste, and keep production moving efficiently. However, one of the most common—and most overlooked—causes of color shifts and quality issues is a dirty anilox roll. Even the smallest buildup of dried ink, coating residue, or debris can significantly alter how ink is delivered to the plate.

At Magnum Inks & Coatings, we understand how crucial clean anilox rolls are for ensuring consistent print performance. As a trusted manufacturer of aqueous flexographic inks, we see firsthand how print quality and efficiency depend on the condition of the anilox. Let’s break down exactly why dirty anilox rolls matter, what happens when they aren’t properly maintained, and how high-quality inks from Magnum can help printers stay ahead.

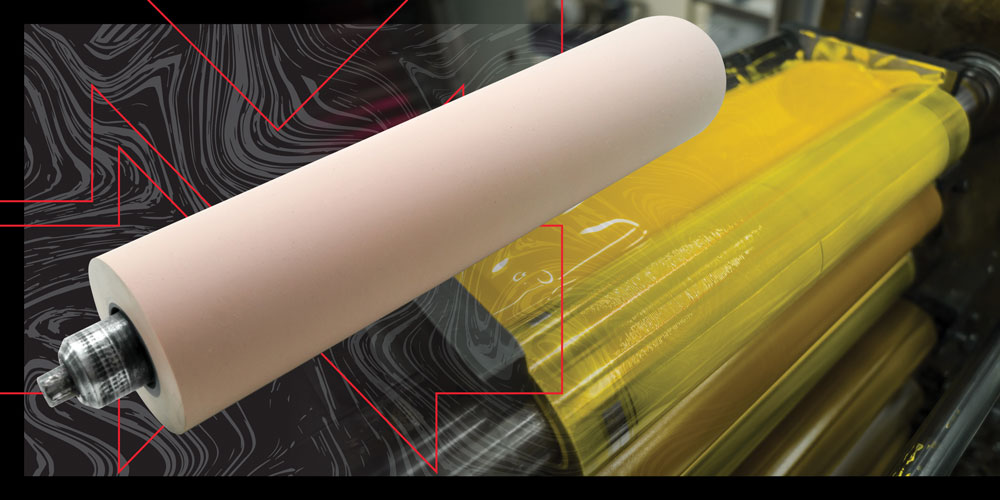

Why Anilox Rolls Are the Heart of Color Control

Anilox rolls are often described as the “heart” of flexo printing because they precisely meter ink onto the plate. Each roll contains millions of tiny engraved cells that are designed to carry a specific ink volume. This volume directly affects the density, consistency, and vibrancy of printed color.

When an anilox roll is clean, each cell transfers ink exactly as intended. But when debris or dried ink starts to clog the cells, ink volume decreases. Over time, the buildup can cause inconsistent ink laydown, uneven coverage, and weak or washed-out colors.

For print shops trying to match brand colors or maintain tight GCMI or Pantone specifications, this is a serious problem. Even slight inconsistencies can force costly press stops, extra cleanup, or reruns—all of which eat into profitability.

The Impact of Dirty Anilox Rolls on Color

Dirty anilox rolls impact print quality in several key ways:

Reduced Color Density – Clogged cells carry less ink, resulting in colors that appear faded, inconsistent, or off-tone.

Uneven Coverage – Partial blockages result in streaking, mottling, or banding on the substrate.

Color Matching Challenges – Brand owners demand precise color matching; a dirty anilox makes it nearly impossible to hit these targets.

Increased Waste – Printers may run excessive makeready sheets or scrap entire jobs due to color issues.

Higher Costs – Extra downtime for cleaning, lost material, and slower turnaround times all reduce overall efficiency.

Put simply, the state of your anilox roll directly determines the strength and reliability of your print colors.

Preventing Color Problems Through Maintenance

Preventing these issues comes down to proactive anilox maintenance. Regular cleaning—both on-press and deep-cleaning offline—helps maintain proper cell volume and ensures consistent ink transfer. Printers who implement routine cleaning programs often see improved uptime, reduced waste, and more predictable results.

Best practices include:

- Flushing the roll thoroughly between jobs to prevent dried ink buildup.

- Using approved cleaning solutions to remove stubborn residues.

- Scheduling deep cleans with ultrasonic or laser cleaning equipment.

- Monitoring roll volume with microscopes or volume testing devices.

Keeping anilox rolls clean isn’t just about maintenance—it’s about protecting color integrity across every print run.

How Magnum Inks & Coatings Supports Consistent Color

While clean anilox rolls are essential, using high-performance inks is just as critical for achieving consistent, vibrant results. Magnum Inks & Coatings is a trusted manufacturer of aqueous flexographic inks designed to deliver reliability and color accuracy job after job.

Our inks are engineered to flow smoothly, transfer consistently, and perform across a wide range of substrates. When paired with well-maintained anilox rolls, Magnum aqueous inks give printers:

- Reliable Color Strength – Formulated for rich, repeatable hues.

- Excellent Flow and Transfer – Optimized for consistent anilox release.

- Low Maintenance Performance – Reduced tendency to build up or clog cells.

- Sustainability – Water-based formulations that align with eco-friendly printing initiatives.

Backed by the Magnum Promise of quality, service, delivery, and value, our inks help printers not only meet customer expectations but also operate more efficiently.

The Bottom Line

Dirty anilox rolls are one of the leading causes of color problems in flexographic printing. From faded density to streaky coverage, clogged cells can compromise quality, increase waste, and create costly downtime. By investing in proper anilox maintenance and pairing it with aqueous inks from Magnum Inks & Coatings, printers can achieve the vibrant, consistent color results their customers demand.

At Magnum Inks & Coatings, we’re committed to being your partner in printing excellence. With trusted flexographic inks and industry expertise, we’ll help you get the most out of every print run.

Ready to see the difference clean anilox rolls and Magnum inks can make? Contact us today to learn more about our complete line of aqueous flexographic inks.

At Magnum Inks & Coatings, we offer an array of ink and coating products, including aqueous and UV coatings. With us, you can find:

Browse our selection to find products to suit your needs, or contact us for custom requests.