How Warm and Cold Weather Months Affect Ink pH—And Why Consistency Matters

In the world of flexographic and corrugated printing, consistent ink performance is essential. One factor that often gets overlooked but plays a critical role in pressroom success is ink pH balance. For aqueous inks, fluctuations in pH can directly affect viscosity, color stability, drying, and overall print quality. Seasonal changes—especially the transition between warm summer months and cold winter months—introduce environmental challenges that can throw ink pH off balance if not managed carefully.

At Magnum Inks & Coatings, we’ve built our reputation as a trusted manufacturer of aqueous inks by producing systems that remain stable and consistent regardless of seasonal swings. Understanding how weather affects ink pH can help press operators and plant managers maintain reliable print performance year-round.

Why pH Matters in Aqueous Inks

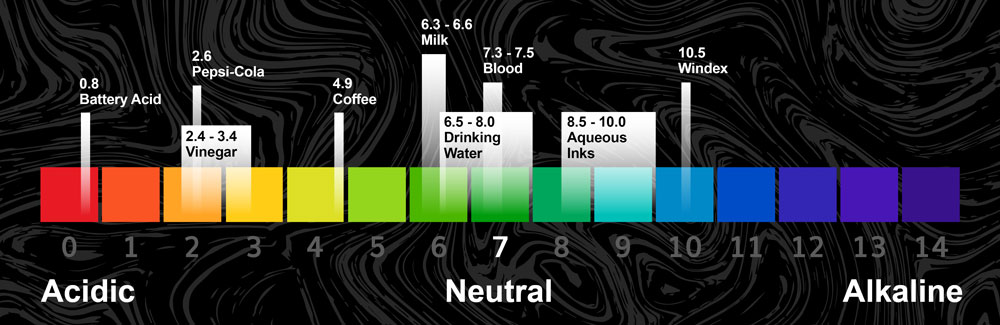

Aqueous inks are water-based, meaning their performance is closely tied to the chemistry of their formulation. The pH range of most aqueous flexo inks typically falls between 8.5 and 10.0, a zone that ensures optimal resin solubility, pigment dispersion, and viscosity control. When ink pH drifts too low or too high:

-

Low pH (<8.5) – Resins may fall out of solution, causing viscosity to rise, leading to poor printability, foaming, or clogged anilox rolls.

-

High pH (>10.0) – Ink can become unstable, pigments may lose brightness, and print quality suffers from weak color strength and poor adhesion.

Maintaining a balanced pH is critical, and that balance is strongly influenced by environmental factors such as temperature and humidity—both of which fluctuate dramatically between summer and winter.

The Effect of Warm Weather on Ink pH

During the summer months, pressrooms often contend with higher temperatures and increased humidity. These conditions can alter ink performance in several ways:

-

Higher Evaporation Rates – Warm temperatures accelerate water evaporation, which can increase ink viscosity and concentrate ink components. As viscosity rises, operators may add water or additives, which, if not balanced, can alter pH.

-

pH Drift from Heat – Heat speeds up chemical reactions in ink systems. If the amines (used to maintain resin solubility) evaporate too quickly, the ink’s pH may drop, leading to increased viscosity and poor flow.

-

Color Stability – Elevated humidity can also interact with paper substrates, impacting absorption and causing color variations.

Summer challenges often mean press operators must monitor ink pH more frequently. Stable aqueous inks, like those engineered at Magnum Inks & Coatings, help minimize these seasonal variations, giving operators confidence in their color consistency.

The Effect of Cold Weather on Ink pH

Winter introduces the opposite set of challenges. Cold air is typically drier, and lower temperatures affect both the pressroom environment and ink chemistry:

-

Slower Evaporation – Cold conditions reduce evaporation rates, which can make inks feel “heavier” and less responsive on press.

-

pH Shift from Storage – If inks are stored in colder areas of a facility or during shipping, the chilled temperatures can temporarily thicken the ink, slow chemical balance, and shift pH outside of the optimal range.

-

Static & Absorption Issues – Dry winter air increases static on substrates, making print quality less predictable. Combined with pH imbalance, this can cause adhesion problems or color inconsistency.

By the time inks warm to room temperature, the pH may stabilize—but not always without intervention. This is why consistent formulations and trusted manufacturing are key to reducing seasonal downtime.

Magnum Inks & Coatings: Consistency Through the Seasons

At Magnum Inks & Coatings, we recognize that your pressroom can’t afford downtime due to unstable inks. That’s why our aqueous inks are formulated for stability and consistency, helping printers maintain pH balance whether it’s the hottest day of July or the coldest day of January.

Here’s how we support year-round performance:

-

Formulation Expertise – Our chemists design aqueous inks with stable pH ranges to minimize seasonal drift.

-

Trusted Quality – Every batch undergoes strict quality assurance, ensuring the ink that leaves our facility delivers consistent results.

-

Reliable Support – Our technical team partners with printers to provide best practices for pH monitoring, storage, and press adjustments throughout seasonal shifts.

-

Made in the USA – With domestic manufacturing, Magnum ensures faster delivery and less exposure to unpredictable environmental changes during shipping.

Best Practices for Maintaining Ink pH Across Seasons

While Magnum’s inks are engineered for stability, operators can take additional steps to protect performance:

-

Monitor pH Frequently – Check pH at the start of each shift and during long runs. Small adjustments early prevent costly rework later.

-

Store Inks Properly – Keep inks in a temperature-controlled environment year-round to avoid unnecessary swings.

-

Mix Before Use – Gently agitate ink to restore uniformity, especially after cold storage.

-

Use Recommended Additives – Only adjust pH with approved additives; avoid over-dilution that can weaken color strength.

-

Train Operators – A knowledgeable team ensures consistent handling and fewer pH-related issues.

Stable Inks, Better Results

Weather is beyond your control, but ink stability doesn’t have to be. By understanding how warm and cold months affect aqueous ink pH—and by choosing a trusted partner like Magnum Inks & Coatings—printers can count on consistent performance, vivid color, and reduced downtime all year long.

When your pressroom demands stability in every season, trust the experts at Magnum Inks & Coatings. Let’s ink together!

At Magnum Inks & Coatings, we offer an array of ink and coating products, including aqueous and UV coatings. With us, you can find:

Browse our selection to find products to suit your needs, or contact us for custom requests.